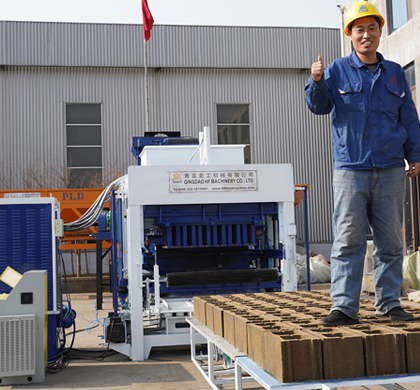

Automatic block making machine can process industrial waste such as tailings slag, ceramsite, perlite (urban construction waste), sand, stone, fly ash, cinder, coal gangue into various new wall materials, such as hollow cement blocks, Pore bricks, standard bricks, etc. do not need to be fired. The Automatic block making machine is a new type of equipment designed and produced by combining advanced technology and engineers with years of research and production experience.

.jpg)

What are the advantages of using Automatic block making machine?

What should I pay attention to when the Automatic block making machine works?

What are the tips for using the Automatic block making machine?

According to the thixotropic phenomenon of the concrete mixture under the action of vibration, the Automatic block making machine can obtain compaction in a relatively small pressure and in a short period of time. The pressure value of the dry and hard concrete mixture is about 0.015 Mpa. Too high pressure value will hinder the vibration of the concrete mixture and affect the compaction effect of the block. According to the above pressure value, generally the pressure generated by the dead weight of the Automatic block making machine can meet the requirements, especially when a vibrator is set on the pressure head, the vibration compaction effect is better than the static pressure effect.

The quality, cleanliness and working viscosity of the hydraulic oil of the block making machine determine the reliability of the Automatic block making machine, as well as the efficiency, life and economy of the block making machine.

There are two types of vibration box used in Hawen block making machine, the one with two shafts allows to fill the hydralic oil between 2.5-3L, the new type of hydrulic vibration box allow to fill the hydralic oil at 2L only.

Above picture showing the new four-shafts vibration box allows to add the volume of hydraulic oil at 2L only.

Anti-wear hydraulic oil must be used, such as Lippo hydraulic oil whose properties are: oil density 0.884G/CM2, flash point 255℃, flow point -9℃, viscosity 68CM2/S (40℃), 8.8CM2/(100℃ ), viscosity index 102. Automatic block making machine adopts this kind of hydraulic oil to stabilize the pressure of the hydraulic oil system and reduce the influence of oil temperature on the viscosity, enhance the wear resistance and corrosion resistance of the system, and it is very beneficial to the reliable operation of the pump and hydraulic valve. . It is strongly recommended to use the above hydraulic oil. If other hydraulic oil is used, it must be consistent with the characteristics of the above oil, and it can be used only after it has been approved.

The Automatic block making machine should use a 10-micron filter device when filling the oil tank, and it is absolutely not allowed to directly fill the oil without a filter device.

.jpg)

In order to ensure the normal operation of the electrical system, the Automatic block making machine must keep the voltage stable, and its fluctuation value should not exceed or be lower than 5-10% of the rated voltage.

Doors or covers of electrical cabinets, junction boxes, and consoles must be closed or covered when the machine is working, and are not allowed to be opened for use to avoid accumulation of dirt.

Quanzhou Hawen Machinery Co.,Ltd is a vital backbone manufacturer for concrete products making machines and molds in China. Powered by innovation and guided by experience, we can provide comprehensive solutions from individual machines, complete lines, to the installation, commissioning and whole life service.

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.